WHAT WE DO

RESPONSIBLE MANGANESE MINING FOR GHANA AND THE WORLD

Ghana Manganese Company Ltd (GMC) is the only manganese producer and exporter in Ghana. The company is a privately-owned mining company (Consolidated Minerals Africa Limited -90% and Government of Ghana-10% free carried).

The company holds a mining concession for manganese over an area of 170 square kilometers in and around Nsuta in the Western Region of Ghana, less than 3% of which has been mined to date.

Nsuta is known for its unique high-grade carbonate ore, which is considered to have one of the highest manganese-to-iron ration ores in the market (Mn: Fe-31) and is low in phosphorus, alumina, and other heavy metal impurities, making it well-suited for both alloy and manganese metal production.

As an experienced owner-operator with a strong focus on operational excellence and innovation, the company targets to be at the bottom of the cost curve of global manganese producers. It has 3 existing pits in total (Pits A, B, and C) with operations currently active in Pit C.

We manage the entire value chain from mine development and drilling to processing and shipping, with a focus on safety, environmental stewardship, and operational excellence.

WHY IT MATTERS

Manganese is a critical industrial metal with wide-ranging applications that make it essential to the global economy, it plays a foundational role in infrastructure, manufacturing, and the transition to clean energy,

CORE TO STEEL PRODUCTION

- Around 90% of all manganese produced globally is used in steelmaking.

- It acts as a deoxidizer and alloying element, durability and workability of steel.

- Manganese is vital in construction, transportation, machinery, and infrastructure development- key drivers of economic growth worldwide.

CRUCIAL FOR BATTERY AND EV INDUSTRIES

- Manganese is a key component in lithium-ion batteries, especially in Nickel-Manganese-Cobalt (NMC) cathodes.

- As demand for electric vehicles (EVs) and grid-scale energy storage grows, manganese’s role in battery manufacturing is becoming increasingly strategic.

SUPPORTS AGRICULTURE

- Manganese is also used in fertilizer production as a micronutrient essential for plant growth.

- It enhances crop yield and quality, especially in manganese-deficient soils – critical to food security in many developing regions.

Manganese is more than a mineral- it’s a strategic enabler of global development. From strengthening cities to powering the green revolution, manganese remains vital to the resilience, sustainability, and future of the world economy.

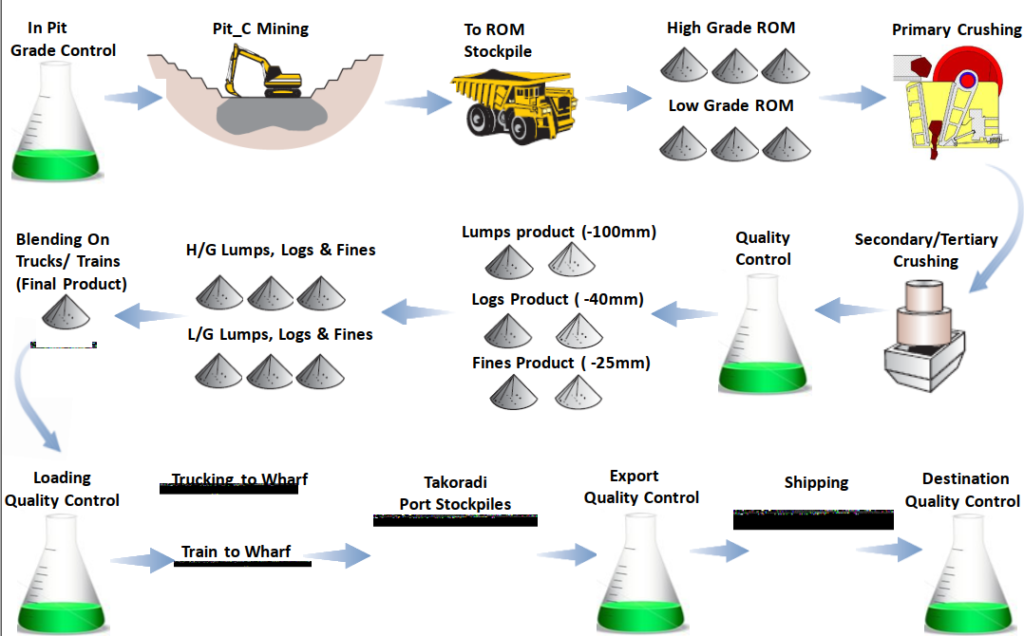

Our Production Process

The method of ore extraction is exclusively open-cast, comprising drilling, blasting, loading, and hauling.

Dry crushing and classification of the carbonate ore into fines, logs, and lumps, by primary and secondary crushing and screening, is undertaken at the carbonate crushing plant. These fines or lumps are stockpiled according to grade and size.

The processing plant receives the bulk blasted ore at the crusher ROM pad and, with the assistance of a Front-End Loader CAT 992K, feeds the material into the crusher ROM bin. The 600t/h jaw crusher crushes the bulk material with no chemical and water added to the appropriate size for screening and secondary crushing into the final product of fines, logs, and lumps for stockpiling and shipment. The crushing circuit incorporates an automatic dust suppression system to minimize dust exposure to the environment.

The processed ore is then transported to Takoradi Port by road and/or rail.

In 2019, the total tonnes of manganese ore mined were 5.38M @ 26.9% Mn and overburden stripping of 64.25M tonnes.

Loading

The primary loading and hauling equipment used at GMC is a combination of GMC’s owned diesel-hydraulic backhoe excavator fleets along with 100t and 150t dump trucks. The manganese ore is hauled to the processing plant whilst the waste is hauled to the waste dump

Processing and Haulage

Primary hauling equipment consists of 100 t and 150t Komatsu and CAT haul trucks. All manganese ore is hauled to the primary crusher located at the exit of the pit rim where the ore is stockpiled at a rompad. The waste rocks are transported to the CN dump.

Manganese ore from the rompad stockpile is processed (crushed and screened with no chemical and water addition) and stockpiled into different categories of sizes for transportation by rail and road to Takoradi Port.

Shipment

Following processing, the Manganese ore product is stockpiled into different size categories. The final product is transported by rail and road to the GMC Takoradi Port terminal. The manganese ore is then loaded aboard Ocean Going Vessels (OGV’s) and exported to its clients.

Closure Strategy

To deliver on our commitments, we establish closure plans for all our active mining areas before we begin operations.

These plans display the steps to be taken throughout the mine life to deliver an effective and sound end to operations, including rehabilitation of the surrounding area and protection of water resources.

These plans are regularly updated, and a proportion of the mine’s annual budget is set aside to make sure all closure obligations are met.

OUR CORE STRENGTHS

What Sets GMC Apart

HIGH-QUALITY MANGANESE ORE

OVER A CENTURY OF MINING EXPERIENCE

STRATEGIC GLOBAL RELEVANCE

COMMITMENT TO SAFETY & ESG

GMC's success is driven by performance, purpose, and sustainable growth in every direction.

Nsuta Mine Process Flow Chart (Mine - Market)