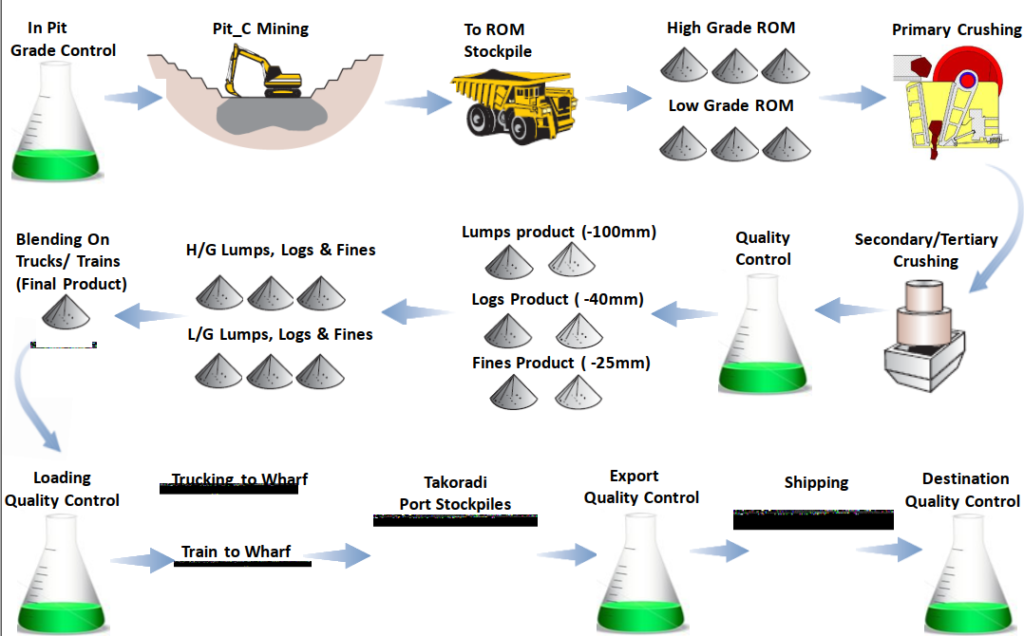

Our Production Process

The method of ore extraction is exclusively open-cast, comprising of drilling, blasting, loading, and hauling.

Dry crushing and classification of the carbonate ore into fines, logs, and lumps; by virtue of primary and secondary crushing and screening, is undertaken at the carbonate crushing plant. These fines or lumps are stockpiled according to grade and size.

The processing plant receives the bulk blasted ore at the crusher ROM pad and with the assistance of Front-End Loader CAT 992K feeds the material into the crusher ROM bin. The 600t/h jaw crusher crushes the bulk material with no chemical and water added to the appropriate size for screening and secondary crushing into the final product of fines, logs, and lumps for stockpiling and shipment. The crushing circuit incorporates an automatic dust suppression system to minimize dust exposure to the environment.

The processed ore is then transported to Takoradi Port by road and/or rail.

In 2019, the total tonnes of manganese ore mined was 5.38M @ 26.9%Mn and overburden stripping of 64.25M tonnes.